Crystal solder paste is a bonding material based on metal alloys such as tin, silver, and copper with a thermal conductivity of around 40W/M.K. It fully meets environmental protection requirements such as RoHS and halogen-free, and is used for LED chip packaging and power device packaging such as diodes.To achieve fusion between metals style="font-family:Microsoft Yahei;color:#333333;font-size:10.5pt;">. The difference between solid crystal solder paste and ordinary solder paste is mainly reflected in the tin powder, packaging and function. The choice of solid crystal solder paste is No. 5 powder or No. 6 powder, and the particles are very small. In terms of packaging, solid crystal solder paste is generally packaged in syringes, mostly 30ml or 10ml. In terms of function, solid crystal solder paste mainly replaces silver glue to solder chips. In addition, do you really understand the die-hardening solder paste? What factors determine the quality of solid crystal solder paste? Earlysun Technology will give you an in-depth explanation below.

1. Viscosity

Crystal solder paste is a thixotropic fluid that can flow under the action of external force. Viscosity is the main characteristic index of the solid-crystal solder paste, and it is an important factor affecting the printing performance: if the viscosity is too high, the solid-crystal solder paste will not easily penetrate the leaky holes of the template, and the printed graphics will be incomplete. The main factor affecting the viscosity of the solder paste is the percentage content of the tin powder. The higher the alloy content, the greater the viscosity.

2. Thixotropic index and slump

Crystal solder paste is a thixotropic fluid, and the slump of the solid crystal solder paste is mainly related to the viscosity and thixotropy of the solder paste. The thixotropy index is high and the slump is small; the thixotropy index is low and the slump is large.

3. Tin powder composition/auxiliary composition

Tin powder composition/The composition of additives and the ratio of tin powder to flux are key parameters that determine the melting point of solder paste, printability, solderability and solder joint quality. Generally, tin powder alloy components are required to be eutectic or near-eutectic as much as possible. The ratio of tin powder to flux is expressed as the weight percentage of tin powder in the solder paste.

4. Tin powder particle size/Shape and distribution

The size, shape and uniformity of tin powder particles are important parameters that affect the performance of solder paste, affecting the printability, demoldability and solderability of solid crystal solder paste. Tiny-particle solder paste has better printability and is suitable for high-density, narrow-pitch products.

The shape of the alloy powder will also affect the printability, mold release and solderability of the solid crystal solder paste. The solder paste composed of spherical particle alloy powder has a low viscosity. The solder paste pattern is easy to collapse after printing. It has good printability and a wide range of applications. It is especially suitable for high-density narrow-pitch screen and metal stencil printing, and is also suitable for drop pattern printing.

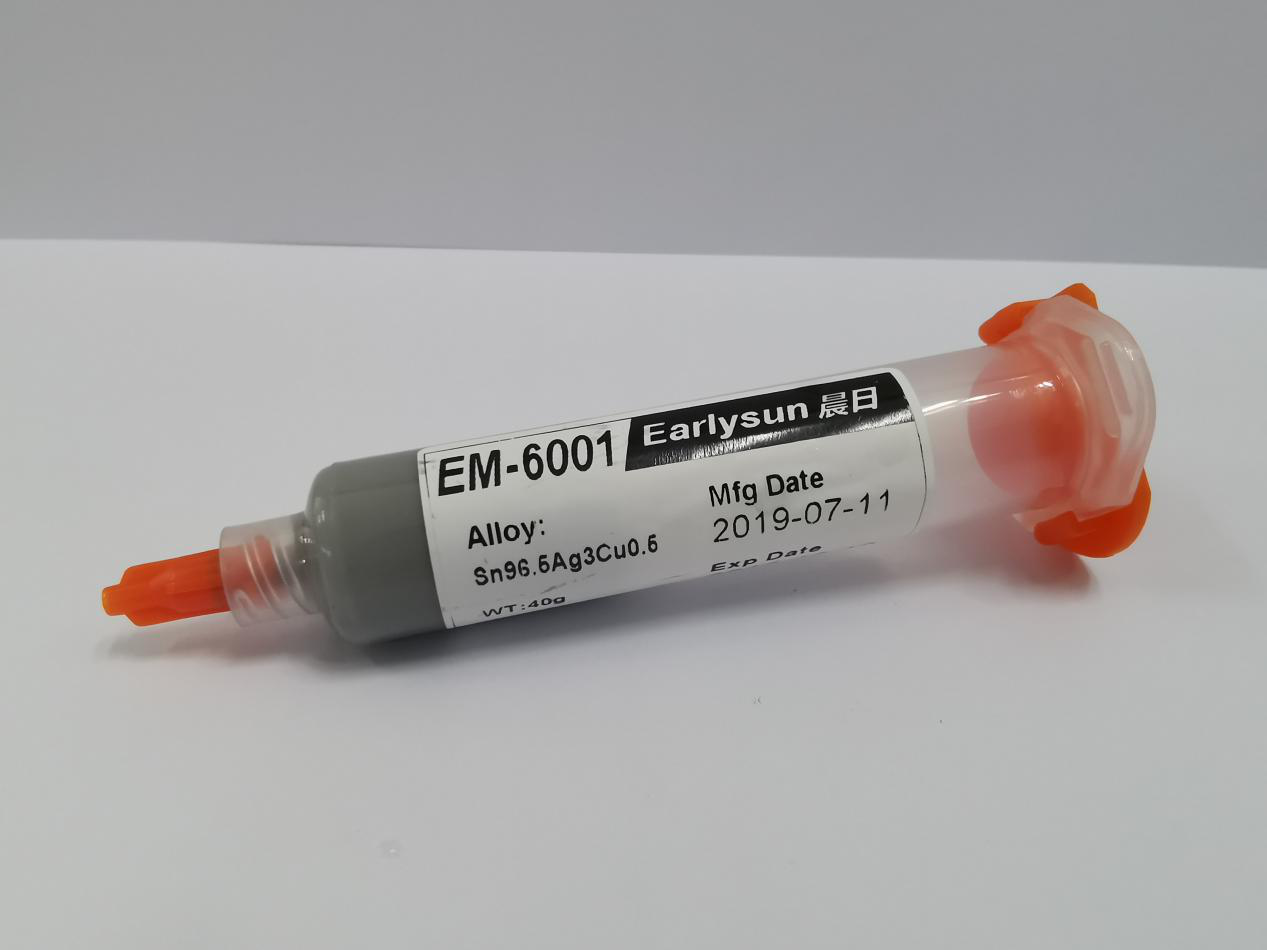

To sum up, the quality of the solder paste is determined. In order to comply with the development trend of miniaturization, small spacing and high density of LED core component chips, Shenzhen Earlysun Technology Co., Ltd.在More than ten years of solder paste R&D and production practiceBased on experience, we successfully developed the EM-6001 series of printing solid solder paste for Mini LED. When used in fine-pitch printing, EM-6001 has good consistency and continuous printability. At the same time, after reflow soldering, the solder joints are full and the voids are small, which significantly improves the production yield of Mini LED products.