Solder paste is a crucial part of the SMT production process. The size of the metal powder in the solder paste, the distribution of metal content, the proportion of flux, the temperature recovery time, the stirring time, the storage environment and the placement time of the solder paste will all affect the quality of solder paste printing.

The components of SMT special solder paste can be divided into two large parts, namely flux and solder powder.

(1) Main components and functions of flux:

Thixotropic agent: This ingredient is mainly used to adjust the viscosity and printing performance of the solder paste, and plays a role in preventing tailing, adhesion and other phenomena during printing;

Activator: This ingredient mainly plays the role of removing oxidized substances on the surface of PCB copper film pads and parts welding parts, and also has the effect of reducing the surface tension of tin and lead;

Solvent: This component is the solvent of the flux component. It plays a uniform role in the solder paste mixing process and has a certain impact on the life of the solder paste;

Resin: This ingredient mainly plays a role in increasing the adhesion of the solder paste, and also protects and prevents the PCB from being oxidized again after soldering. This ingredient plays an important role in fixing parts.

(2), Solder powder:

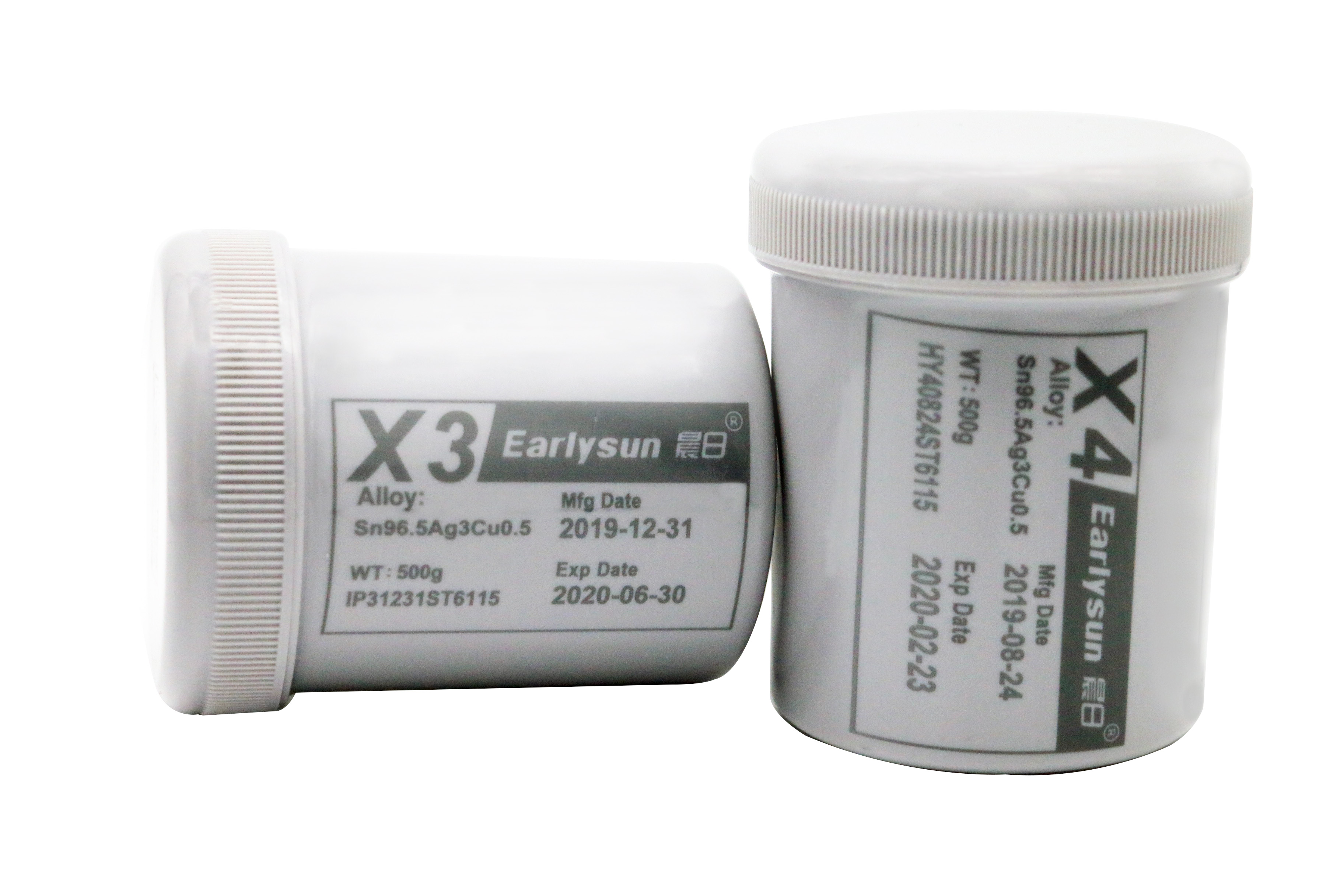

Alloy solder powder is the main component of solder paste, accounting for approximately 85-90% of the solder paste mass. Commonly used alloy solder powders include the following: tin-lead (Sn-Pb), tin-lead-silver (Sn-Pb-Ag), tin-lead-bismuth (Sn-Pb-Bi), tin-bismuth (Sn-Bi), tin-bismuth-silver (Sn-Bi-Ag), tin-silver-copper (Sn-Ag-Cu), etc. The composition and proportion of alloy solder powder, as well as its shape, particle size and surface oxidation degree have a great influence on the performance of solder paste.

When the metal content is high, the slump of the solder paste can be improved, which is beneficial to the formation of plump solder joints. Since the amount of solder is relatively small, the flux residue can be reduced and the appearance of tin beads can be effectively prevented. The disadvantage is that the printing and welding process requirements are stricter. When the metal content is low, the printability is good, the solder paste is not easy to stick to the scraper, the blank has a long life, good wettability, and easier processing; the disadvantage is that it is prone to collapse and defects such as tin beads and bridges. Therefore, appropriate tin powder specifications must be selected.

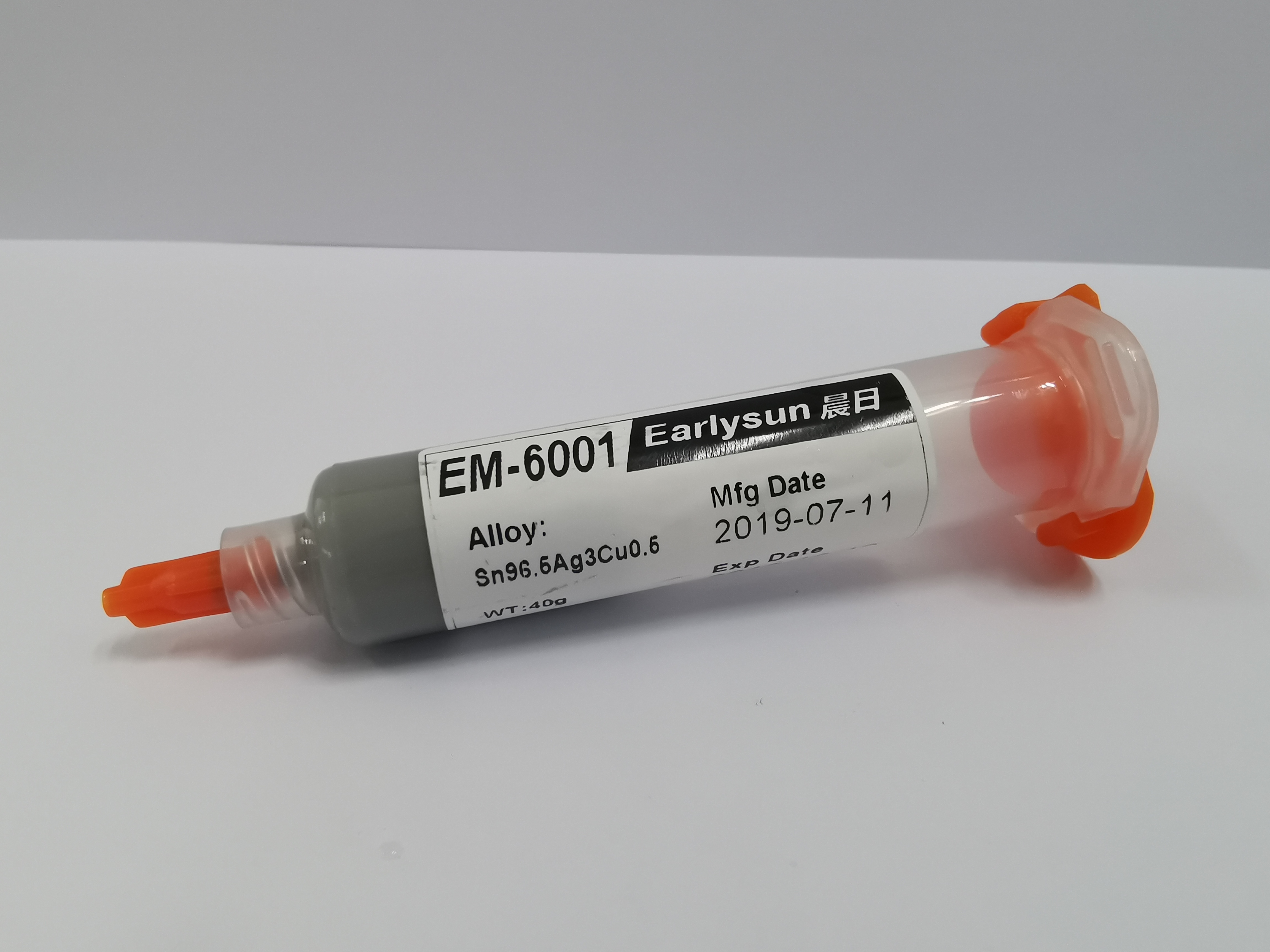

The shape of alloy solder powder can be divided into spherical and elliptical shapes. Ball solder has good properties. The particle size of normal alloy solder powder is 200/325, and finer pitch printing requires finer metal particle size. The size and shape of the selected tin powder particles are generally determined by the opening size of the printing stencil or the stencil or the caliber of the syringe. Tin powders of different particle sizes should be used for different pad sizes and component pins. Small particles cannot all be used, because small particles have a much larger surface area and can easily increase the burden of flux when treating surface oxidation.