Frequent Solder Beads in SMT Soldering?

5 Root Causes + Solutions Fully Analyzed!

🛠️ Process Optimization · Defect Troubleshooting · Earlysun Tech Post

In SMT (Surface Mount Technology) soldering, solder beads are the "number one enemy" for engineers. How to precisely snipe solder beads? This article deeply disassembles the causes of solder beads from four dimensions: production process, materials, design, and environment, and Earlysun Technology provides practical solutions!

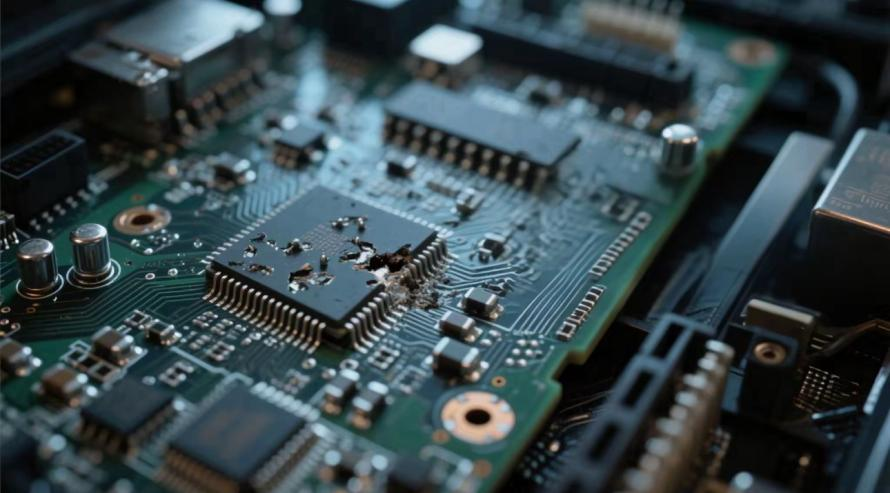

🚨 I. Hazards of Solder Beads: Small Problem, Big Risk!

- Electrical Short Circuit: If solder beads remain on high-density PCBs, they may cause short circuits in adjacent lines.

- Reduced Reliability: In vibration or varying temperature environments, solder bead detachment may lead to solder joint failure.

- Poor Appearance: It is not uncommon for consumer electronics products to be returned by customers due to solder beads.

II. 5 Major Culprits of Solder Beads and Solutions

1. Solder Paste Printing: The First Line of Defense Falls

- Stencil aperture too large/thick → Excessive solder paste deposition.

- Printing offset → Solder paste "strays" to non-pad areas.

- Solder paste slump → Insufficient viscosity or improper warming.

- • Stencil Optimization: Design apertures at 80%-90% of pad area; reduce thickness to 0.12mm.

- • Process Upgrade: Use nano-coating stencils, control squeegee pressure and speed.

2. Reflow Profile: The Fault of Temperature "Roller Coaster"

Preheating too fast causes violent flux evaporation; peak temperature too high causes solder spattering; cooling too slow.

- • Preheat Zone: Fully evaporate solvents.

- • Reflow Zone: Set peak temperature according to solder type.

- • Cooling Zone: Rapid solidification suppresses solder beads.

3. Solder Paste Quality: Wrong Material, Total Loss

Solder paste oxidation/moisture absorption; metal powder too fine (<20μm); insufficient flux activity.

- • Selection: Choose solder paste with high metal content (≥90%) and uniform particle size (e.g., Type4).

- • Storage: Refrigerate (2-10°C), warm up for 4 hours and stir for 3 minutes before use.

4. PCB Design: Details Determine Success

Pad spacing too small; solder mask defects.

- • Pad spacing ≥0.2mm to avoid bridging.

- • Adopt "teardrop" pad design.

- • Solder mask thickness uniform, fully covering non-pad areas.

5. Environment and Operation: Invisible Killers Not to be Ignored

High workshop humidity causes solder paste moisture absorption; insufficient placement machine precision.

- • Environment: Temp 22-28°C, Humidity 40-60% RH.

- • Equipment: Calibrate placement machine regularly, reduce component placement pressure.

III. Summary: Systematic Thinking to Cure Solder Beads

Prevention and control of solder beads is by no means a single-point breakthrough; it requires full-link control from "Man, Machine, Material, Method, Environment".

Earlysun focuses on "twenty years of solder paste R&D, craftsmanship for zero solder beads". Facing the problem of solder beads, Earlysun Technology relies on years of R&D and production experience to launch a series of high-performance solder paste products, solving problems for electronics manufacturing enterprises.