Tech Adaptation & Practice |

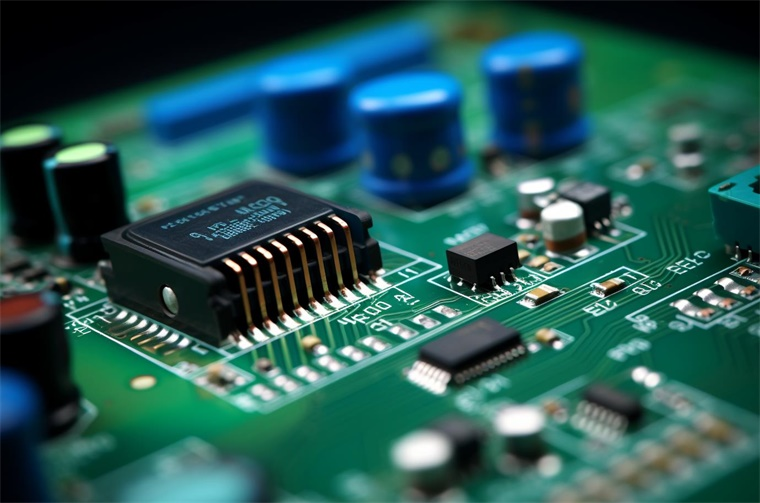

Industry Exploration and Earlysun Practice in Electronic Manufacturing Alloy Detection

🔬 Quality Control · Core Competitiveness · System Construction

In the process of the global electronics manufacturing industry iterating towards high precision and high reliability, alloy materials act as core interconnection and structural components. Precise control of their composition directly determines the performance boundaries and service life of end products.

Earlysun Technology not only focuses on solving its own detection pain points but also provides a reference technical path for the industry through practical exploration. Its core practice is not just simple equipment upgrading, but systemic innovation based on common industry problems, demonstrating the complete logic of "equipment selection - process optimization - technology output".

I. Common Industry Pain Points: The Adaptation and Precision Dilemma of Detection Systems

The core challenge of alloy detection is essentially the adaptation problem of "equipment performance - sample characteristics - production demand". In the field of electronics manufacturing, this problem is particularly prominent:

📉 1. Efficiency Bottleneck of Detection Models

Third-party testing cycles are long and cannot meet immediate needs, increasing rework risks; enterprise self-built detection systems face obstacles such as difficult equipment selection and high technical thresholds.

🧩 2. Adaptation Gap Between Equipment and Samples

Composite system materials like solder paste are difficult to prepare samples from (flux residue, element segregation), while mainstream instruments lack targeted optimization, leading to large fluctuations in detection data.

🛠️ 3. Industry Shortfall in Sample Preparation Technology

The industry lacks unified sample preparation specifications. Empirical operations easily lead to sample defects (pores, cracks), seriously affecting the credibility of detection results.

II. Technical Principle and Industry Practice: Application and Optimization Direction of Direct Reading Spectrometers

Direct reading spectrometers have advantages such as fast detection speed and high precision, making them the mainstream choice for industrial detection. However, to fully utilize equipment performance, two key issues need to be solved:

- • Scientific Nature of Equipment Selection: Precise selection based on enterprise detection needs. For example, for detecting multi-series alloys like tin-silver-copper, tin-bismuth, tin-antimony, equipment with wide element coverage and high precision must be chosen.

- • Adaptability of Sample Preparation Technology: For composite systems like solder paste, sample preparation processes need targeted optimization (e.g., removing flux, controlling melting temperature and stirring rate) to avoid sample defects affecting results.

III. Earlysun Practice: The Complete Path from Problem Orientation to Technology Output

Earlysun Technology's alloy composition improvement project has gone through multiple stages including initiation, selection, tackling key problems, and verification, building a scientific and complete independent detection system:

🎯 Precise Initiation, Solving Model Pain Points

By introducing precision detection equipment, realize full-process quality control of "raw material detection upon entry, production process monitoring, and finished product re-inspection upon exit".

🧪 Tech Attack, Breaking Through Sample Preparation Bottlenecks

Based on material thermodynamics principles, mastered the thermal decomposition laws of flux in solder paste, solving problems such as flux residue, element segregation, and uneven sample surfaces during sample preparation.

IV. Industry Inspiration and Future Outlook

High-quality detection equipment is the foundation, but only by combining specific application scenarios for technical adaptation and process optimization can equipment value be fully released. As the electronics manufacturing industry's requirements for alloy material performance continue to rise, alloy detection technology will develop towards more precise, efficient, and intelligent directions.

Earlysun Technology will continue to deepen its presence in the field of electronic manufacturing detection, injecting lasting momentum into the high-quality development of the industry with more practice-based technological innovations, and working with the entire industry to build a precise, efficient, and reliable alloy detection ecosystem.