[Technical Analysis] Solder Paste Technology Breaks Through Tin Whiskers

Guarding Electronics Manufacturing Reliability

🔬 Microscopic Mechanism · Stress Control · Solutions

I. Formation and Growth Conditions of Tin Whiskers

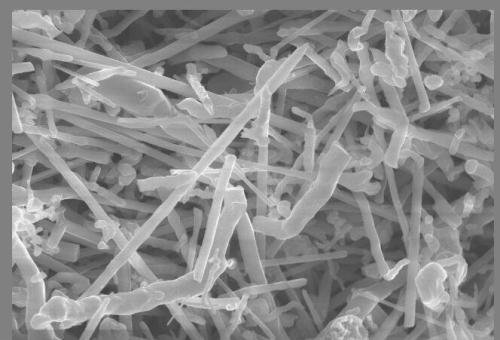

Tin whiskers are whisker-like pure tin crystals naturally growing from tin or tin-plated metal surfaces. Their formation involves physical displacement of metal crystals, usually caused by stress after welding. Their growth is a room-temperature creep behavior under stress gradient, requiring three simultaneous conditions:

-

1. Stress Source:

This is the driving force for tin whisker growth. Compressive stress generated on the tin layer by the intermetallic compound Cu6Sn5 formed at the Cu/Sn interface is a common stress source. -

2. Oxide Layer Constraint:

Provides certain spatial limitations for the diffusion and aggregation of tin atoms. -

3. Long-range Diffusion of Sn Atoms:

Allows tin atoms to move under stress and form tin whiskers.

II. Mechanism of Tin Whisker Formation

The growth mechanism of tin whiskers is not yet fully understood, but studies show that compressive stress inside the plating layer is the main driving force for whisker growth. Specifically, in electronics manufacturing, tin and copper diffuse into each other to form intermetallic compounds (IMC). This process rapidly increases internal stress in the tin layer, prompting tin atoms to diffuse along grain boundaries, thereby producing tin whiskers.

Compressive stress comes from various sources, including:

- ● Mechanical Stress: May come from squeezing during component installation.

- ● Thermal Stress: Generated by differences in thermal expansion coefficients of different materials during electronic product operation.

- ● Chemical Stress: Closely related to chemical reactions between tin and other metals.

III. Relationship Between Solder Paste and Tin Whiskers

The use of solder paste is closely related to the formation of tin whiskers. Solder paste components, printing, and welding processes all affect tin whisker formation:

Types and proportions of alloy elements and flux quality will change the crystal structure, internal stress state, and oxide layer integrity of the tin layer.

Solder paste printing thickness determines subsequent tin layer thickness; too thick or too thin may increase the risk of tin whisker growth.

Reflow temperature profile (heating rate, peak temperature, dwell time) affects the formation rate and morphology of IMC, subsequently affecting tin whisker generation.

IV. Earlysun Technology's Response

As a leader in electronic chemical products, Earlysun Technology has taken a series of effective measures in solder paste R&D and process control to address the tin whisker problem.

(1) Solder Paste R&D

- • Optimizing Alloy Ratio: Carefully adjusting the proportion of alloy elements in solder paste to optimize the crystal structure of the tin layer.

- • Strict Flux Control: Ensuring high-quality flux forms a uniform and stable oxide layer on the tin surface after welding, which constrains tin atoms, prevents random diffusion, and inhibits tin whisker growth.

(2) Solder Paste Printing and Welding Process Control

- • Precise Printing Thickness Control: Using advanced printing equipment and precise process control to ensure appropriate solder paste printing thickness, avoiding uneven or accumulated stress caused by thickness issues.

- • Optimizing Reflow Profile: Carefully debugging heating rate, peak temperature, and dwell time. Slow heating rate reduces thermal stress; appropriate peak temperature and dwell time ensure ideal IMC growth.

Tin whisker issues can cause short circuits between components and leads, leading to electronic product failure.

Earlysun Technology's continuous innovation in solder paste products and processes provides reliable solutions for electronics manufacturing enterprises. We will continue to uphold the spirit of professionalism and innovation, working deeply in the field of electronic chemical products to help the electronics manufacturing industry move towards a higher quality development stage.