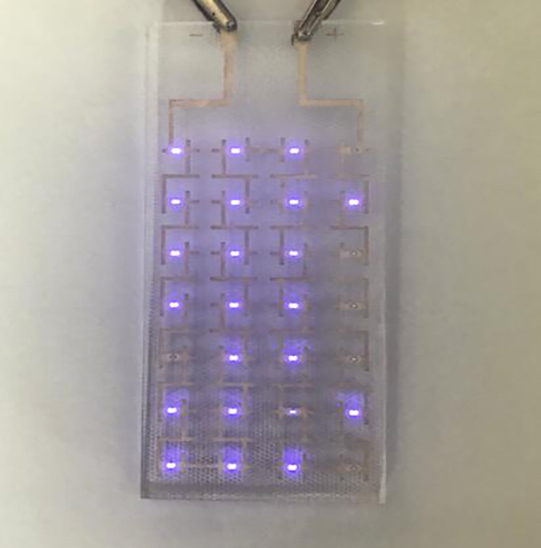

The LED flip-chip

package has better thermal conductivity than the packaged product. The

advantages of flip-chip packaging are obvious in LED products with high heat

dissipation, especially power-intensive light sources. Although the flip-chip

packaging method has more advantages, if the process control is not good, the

impact on the product quality is quite obvious, and sometimes the flip-chip

heat dissipation advantage may be made a disadvantage. The flip-chip packaging

process is very different from the formal packaging, and the differences in

equipment, materials, and processes have caused many problems for packaging

friends. Morning Technology has been researching and optimizing and

re-optimizing LED solid crystal solder paste for more than 10 years. In the

field of flip-chip packaging research for 10 years, we have deep understanding

of LED flip-chip packaging materials, processes and equipment, and share some

things in the industry. Help some new friends.

Void solution -

optimize pad coating materials, optimize solder paste formulation system,

optimize welding pipe control;

Leakage solution - avoid solder paste and tin short circuit, prevent electrode insulation material from tin leakage, avoid substrate or wafer itself;Product high temperature solution - control the melting point of solid crystal solder paste, optimize heat dissipation;

Official WeChat

Official WeChat